Regular CT Cons

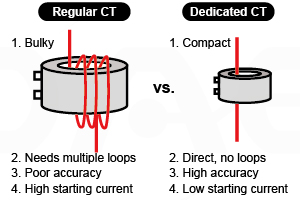

Current transformers (CTs), sometimes also called current sensors, industry standard versions commonly have 5A as its output. They have the following disadvantages when used in branch circuits.

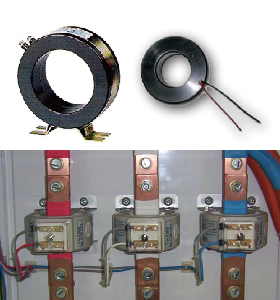

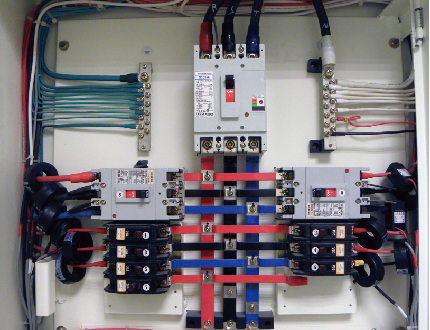

Regular CTs are large and will occupy a lot of space in a panel.

Branch circuit loads often do not exceed 75A, but since regular CTs have poor accuracy, they need to be wound multiple times to compensate.

During retrofitting, the existing layout and wiring constrains any new additions, since regular CTs are large, it is often difficult if not impossible to fit them.

Why the Need?

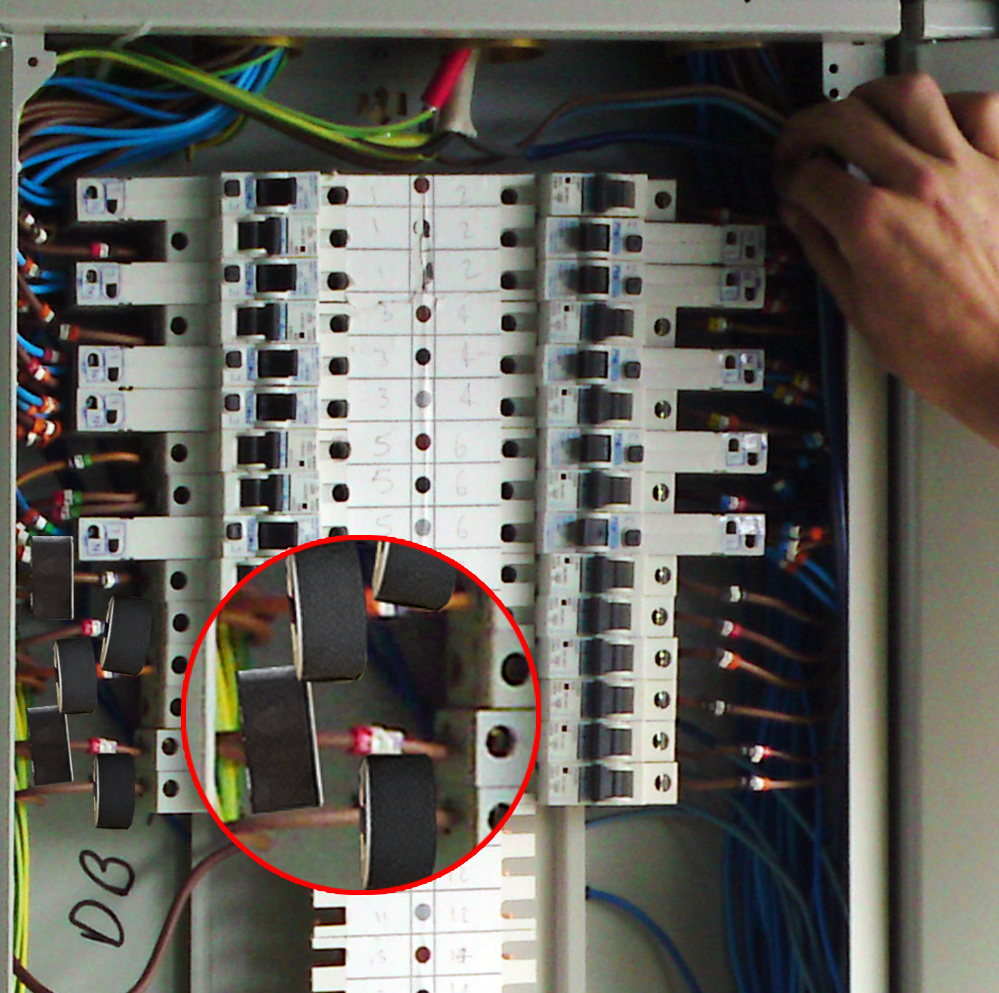

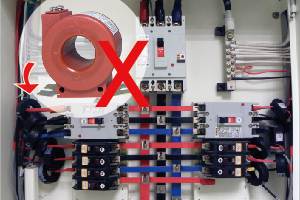

Regular CTs won't fit in existing panels

But dedicated CTs are small enough to fit.

When high accuracy is needed

Dedicated CTs can be as accuracte as 0.3%, much better than the 1% of regular CTs.

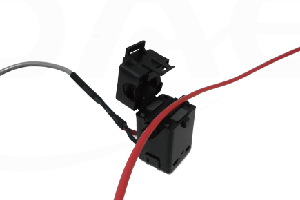

Installing a CT w/o interrupting power

Split core CTs can be used, they can be installed easily w/o lengthy disruptions, reducing both time and effort.

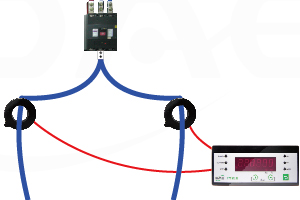

Same circuit, but branching wiring

Small CTs allow for parallel connections.

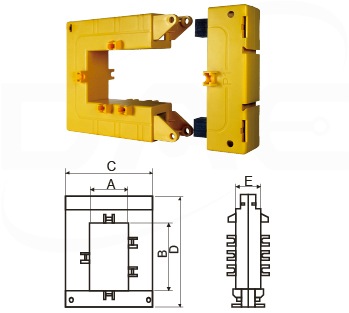

Regular Split Body

| Outer Dimensions (W x H x D) | Window Dimensions (A x B) |

|---|---|

| 114 x 145 x 32 mm | 50 x 80 mm |

When doing temporary testing or when demands require that the power cannot be interrupted, then the regular split body type of CT is ideal. They are available with various capacities including 100A, 200A, 300A and 600A. They are all regular 5A output and can thus be used with any meter that accepts 5A as its CT input.

Installation

New Panel

Since dedicated CTs are small, they demand much less space when placed in new panels, as such the panels needed can be much smaller than normal. They are also low cost and aesthetically pleasing.

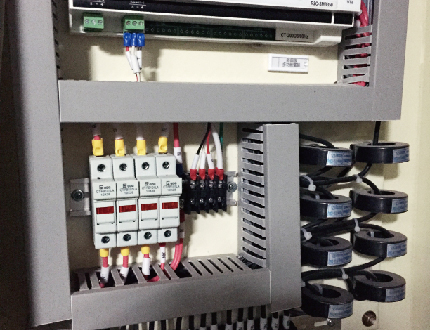

Existing Panel Retrofit

When an existing panel needs to be metered, CTs are absolutely required. But since space is cramped, regular CTs will not fit in between the wires, whereas dedicated CTs are small enough to fit.

Regular CT Datasheet

Regular CT Datasheet